LASER WELDING

Addit gives the new meaning to the quality of welding!

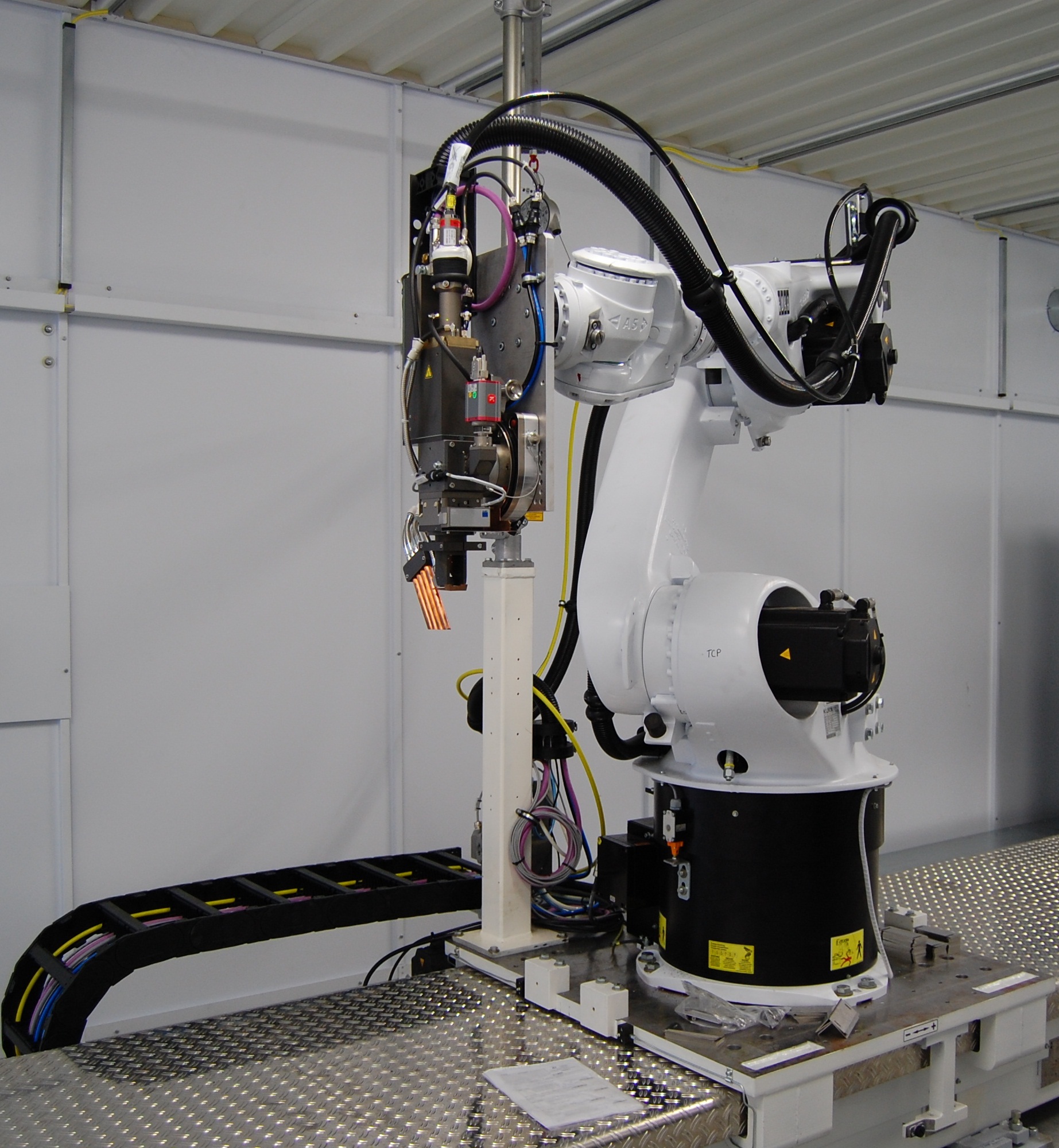

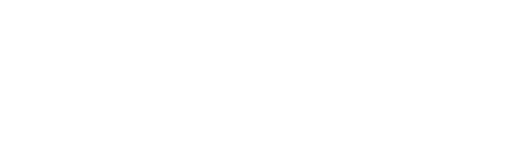

In 2012 we bought a new laser welding TRUMPF YAG-Laser TruDisk. The innovative laser beam welding has been designed and prepared thanks to Addit's cooperation with the Welding Institute in Gliwice and company Trumpf. This was preceded by research on a fluent change of the position of the focal length. The key parameter is the ability to control the laser's focal length automatically, which allows to optimize quality of the weld and its surrounding.

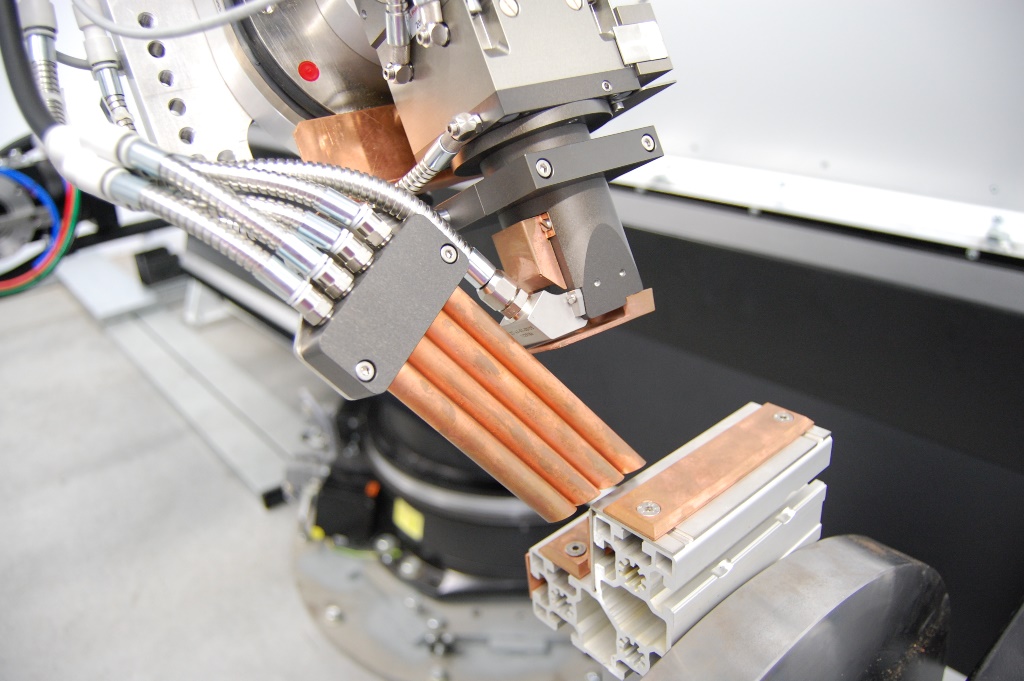

Laser welding with the head placed on the robot is easy to automate. The high power density allows to weld materials with high speed. During laser welding,welding, a narrow heat-affected zone is formed, which allows to minimize the distortion of welds. With the laser welding, we can achieve a resistant and aesthetic weld using no binding material.

Technical specifications:

- Laser TruDisk 3302, 3300 W output power

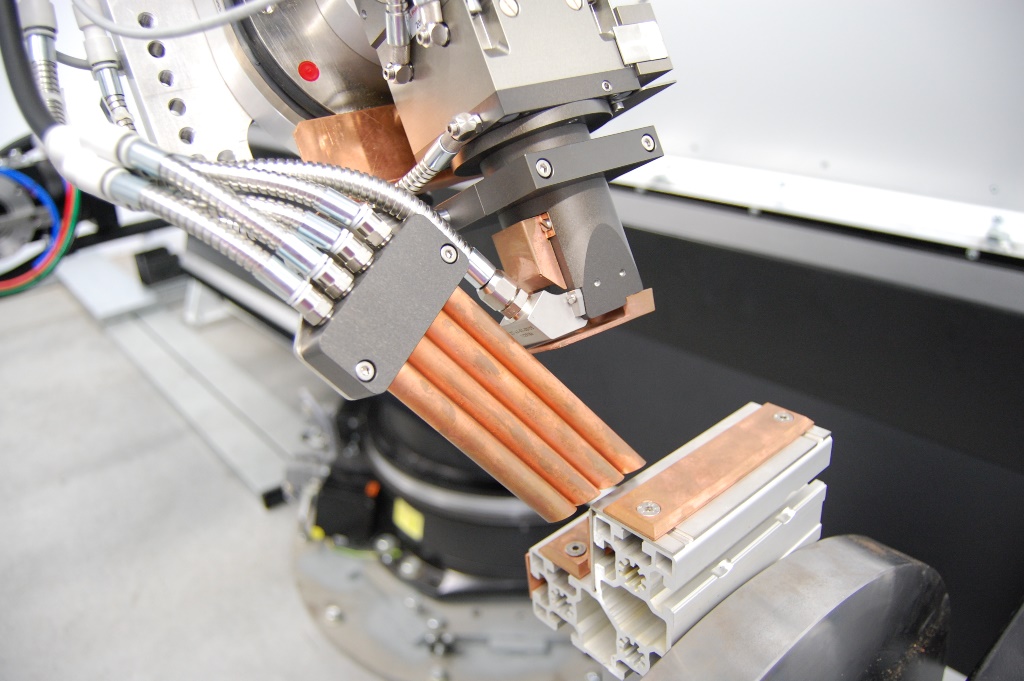

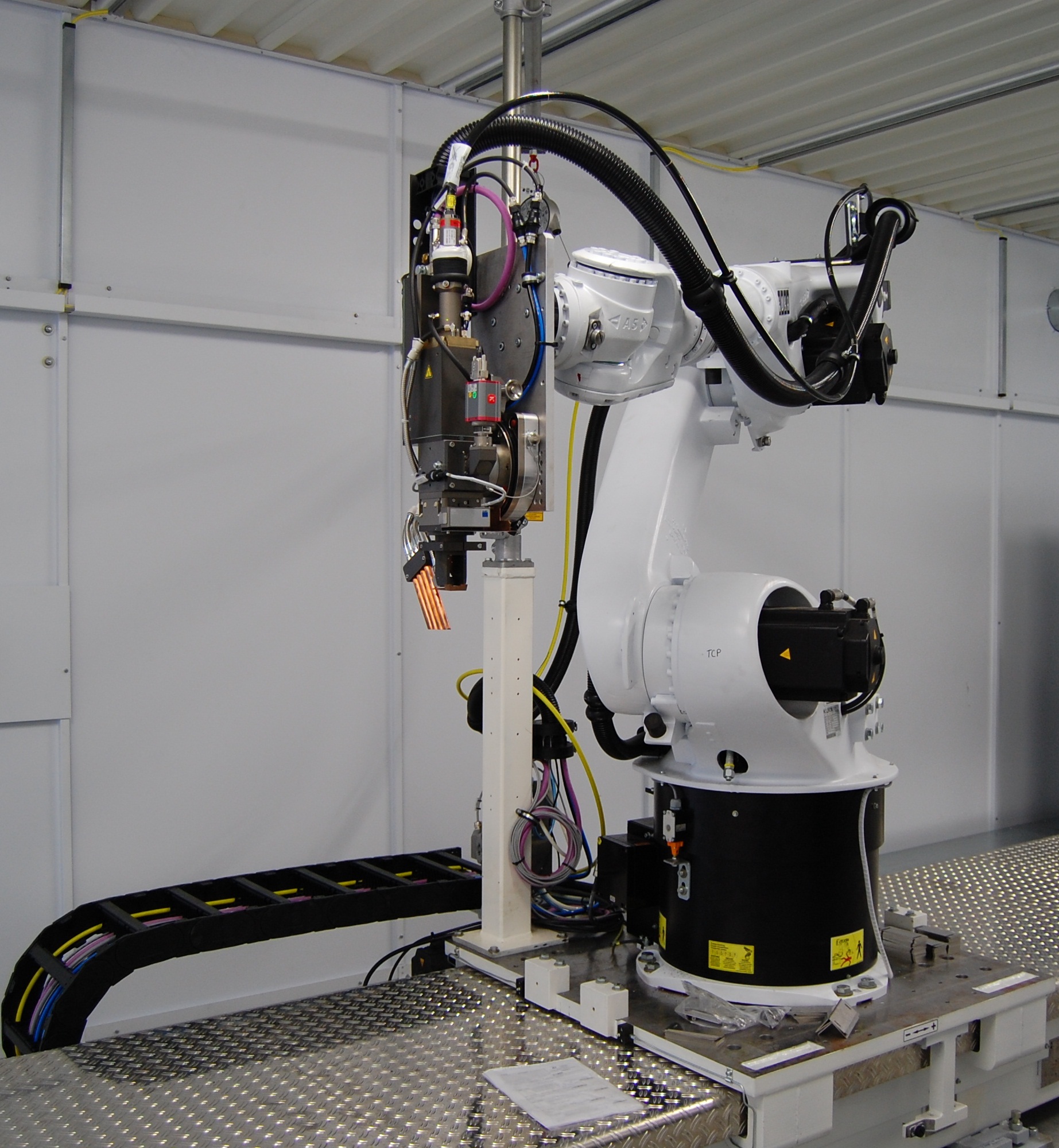

- Beam guidance system: a fiber optic cable LLK-D 04, length 30m, laser fiber diameter of 400 microns.

- The working head BEO 7000210s laser welding.

- Collimation 0 ° to the defocus, CCD camera, the camera's power up to 30 m, BNC video cable up to 10 m

- Lens focal length f = 200 mm, protective cartridge

- Magnetic force protecting against the effects of collisions

- Robot welding KUKA30 / 3, 6-axle articulated kinematics

- Cab of protection; protective glass in accordance with DIN A4

- Manipulator with two rotary axes - KFP3-V2H250

The advantages of laser welding:

- High speed and purity of the process,

- High power density

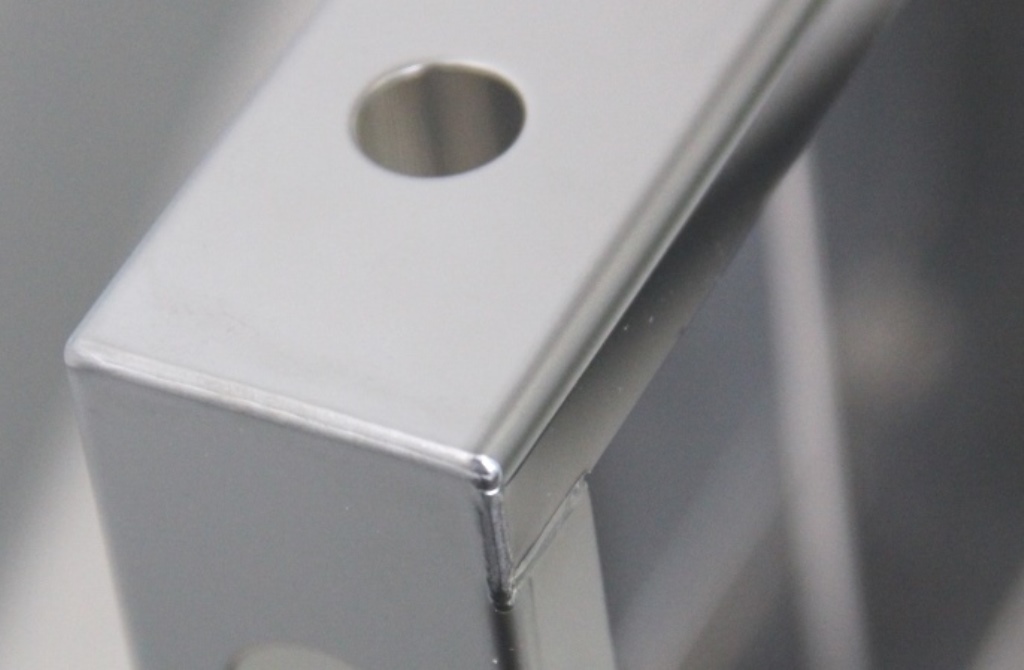

- High quality of welds; They are strong and aesthetic.

- It does not require adhesives

- Welding with high precision

- The ability to combine hard-to-weld materials.

- Easy to automate

Quality requirements laser welded materials:

- The surface must be cleaned and decreased

- The maximum gap of 0.25 mm welding

- Types of materials that can be welded: carbon steel, stainless steel and aluminum.

Laser welding:

We recommend you our services!

Inquiries sent us to sales@addit.pl or info@addit.pl

BACK

BACK