select language:

|

||||

|

|

|||

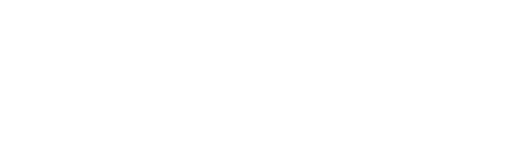

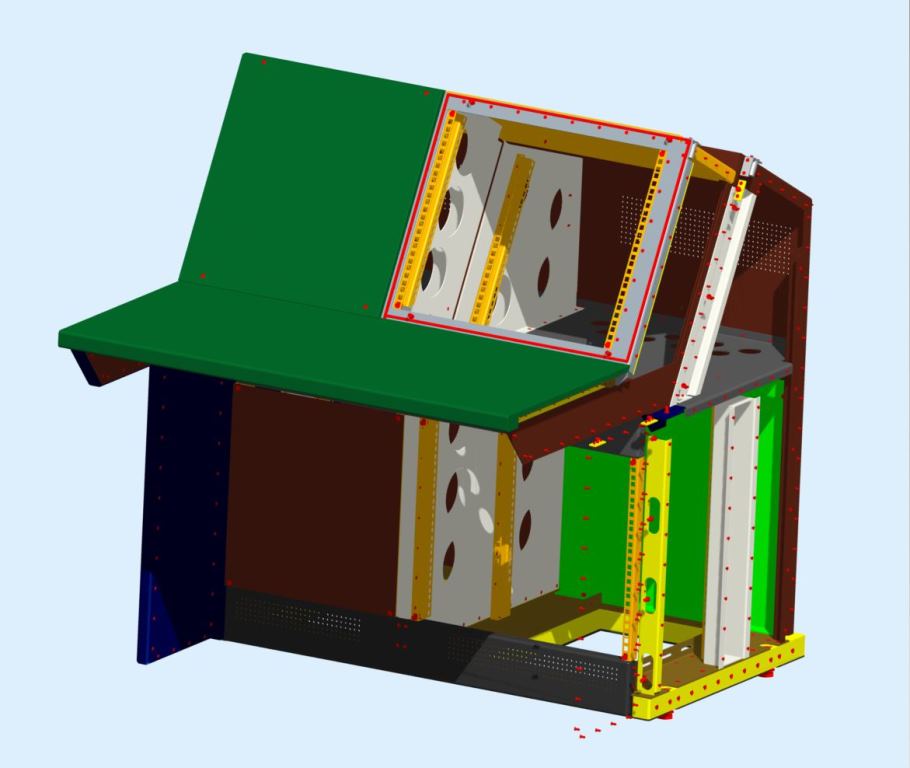

ENGINEERING AND CONSULTINGAddit constantly focuses on comprehensiveness and flexibility in servicing our partners.We offer our clients full support and commitment from the earliest stages of project’s lifecycle. Knowledge and broad experience in sheet metal processing allow us to anticipate the challenges we may encounter during product development and propose our partners the best solutions. In construction and design we concentrate on functional quality and proper technological process. Innovation in Addit is that client receives complete technological process within 3D model. The core of our philosophy is a 3D model of good quality, created on the basis of many years of experience, following all the rules needed for effective sheet metal production. Proper 3D model allows for taking full advantage of tools offered by Industry 4.0. A well-prepared 3D model gives possibility to reduce or eliminate human factor in technological process preparation, which is usually the weakest link. The better the 3D model, the less human involvement in production preparation process needed. We engineer in such a way, that human interference in the process is no longer necessary.

As a manufacturing company we poses a solid tooling base, which we use in our designs. A part of our strategy is to move away from special tools and templates – we anticipate material behaviour and act accordingly. This approach significantly accelerates preparation for production and reduces initial costs. Our goal is to base all production processes on the 3D model. In order to do that we leave the traditional Bill of Material in favour of Bill of Information. This allows us to:- automatically prepare CNC programs These innovations significantly shorten production preparation process and eliminate potential quality threats, resulting from improper technological preparation.

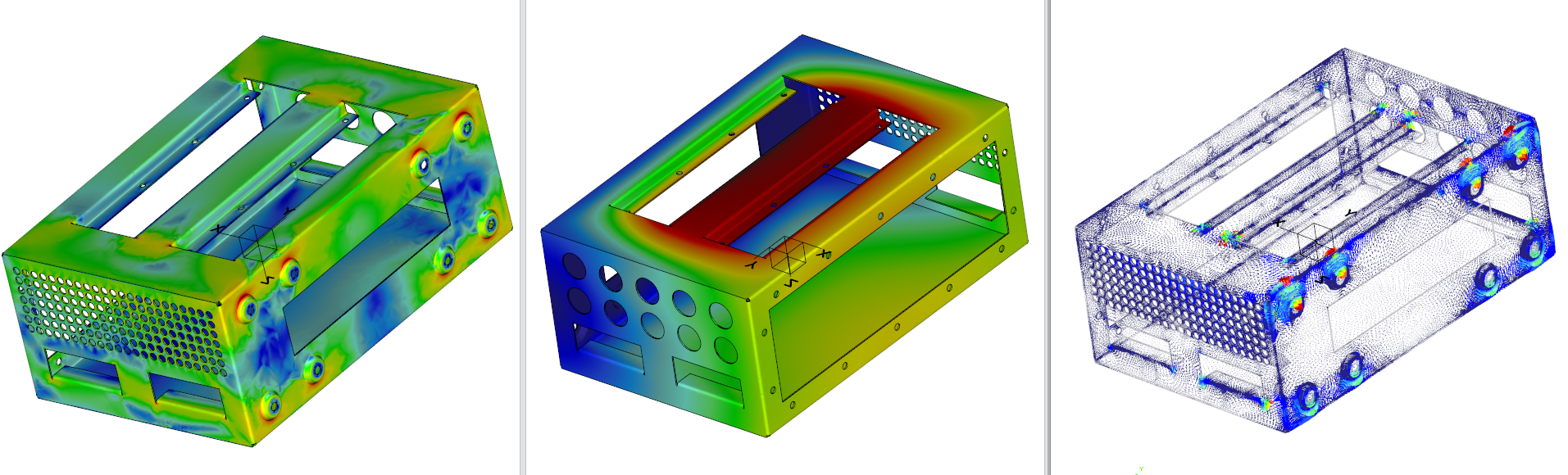

We may also subject our designs and concepts to FEM analysis. Our experience allows us not only to prepare the model and define assumptions properly, but also to draw the right conclusions. We end the analysis with a technical report covering the scope of calculations, testing methodology and results together with conclusions.

We put great emphasis on digital continuity in our company. Our partners benefit from all optimizations, which we introduce during production and always receive the newest documentation, after each change, until the end of product’s lifecycle. We present the projects to our clients using Augmented Reality. With a phone or a tablet the user may see the model of its true size where the actual device will be operated – it improves the overall experience and helps to make better decisions.

Our strength is the team of specialists – all engineers are experienced in sheet metal production and have complete understanding of technological production processes. We understand how much commitment the initial phase of project-implementation requires, which is why we have a Project Account Manager exclusively for engineering department. We follow the Agile philosophy – we know that project objectives and assumptions may change many times during the design phase – we are prepared for that. We are happy to support our clients with experience and advice in choosing the right solution. Our experienced engineers offer also the possibility of working at the customer’s or anywhere in the world. Close cooperation between the engineers from both companies allows for taking advantage of the synergy effect by integrating comprehensive knowledge and experience in various fields: precise sheet metal processing on Addit’s side, combined with core competences of our partners. In our work we use following CAD/CAM software: Creo Parametric, Inventor, SolidWorks, Cadman, Radan, TruTops Boost and others.

Our Build to Spec services include:- Concept and design development |

BACK

BACK